I think everybody is too preoccupied with the beauty and elegance of ipe decking that they don’t acknowledge the problems that come with it. It’s high time now that this needs to be discussed.

Some problems with ipe decking include its hardness, lack of uniformity in boards, high maintenance needs and expensiveness. It also is problematic because it is extremely sensitive to changes in the climate.

Let’s find out more about the problems associated with Ipe decking.

1. Ipe Wood Is Too Hard

The Janka Hardness scale is used to calculate and compare the hardness of materials. Ipe is ranked among the top ten toughest woods by most reputable sources.

The majority of tropical forests, such as Tigerwood, Cumaru, and Ipe, are tough and dense. Because of their high density, they are easily fractured. They especially end up fractured if proper drilling has not been done. Working with such woods necessitates the use of sharp tools during installation.

You can consider purchasing a [amazon link=”B0787HSW6N” title=”Board Bending Straightener”/] and a [amazon link=”B0052FSLO0″ title=”Pre-drilling and counter skinning tool”/] to help you with the installation!

[amazon box=”B0787HSW6N”]

[amazon box=”B0052FSLO0″]

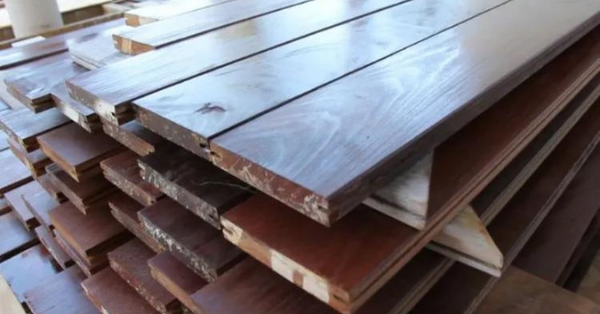

2. It is Difficult to Find Uniform Colors in Ipe Boards

Since it’s difficult to find boards that are all the same color, creating an IPE deck with a single solid color can be troublesome. You’ll get boards that are all the same color if you want plastic or composite woods. Natural ipe wood, on the other hand, comes in a variety of shades ranging from three to five.

Of course, for people who are artistic and who prefer variety in their aesthetics would love the color variation. However, it could be a turn off for someone who desires consistency.

3. Acclimation can Be Problematic for Ipe Wood

The process of acclimating to a new environment or set of circumstances is known as acclimation. This is a method that is often ignored or poorly handled when installing Ipe Decking. It is applicable to almost all types of wood decking and flooring.

Even if you’re using Ipe outdoors, it must first acclimate to the weather. If it doesn’t, the chances of surface cracks and separation will increase with time.

Brazilian hard wood needs to sit in the warehouse for months to adjust according to the environment. Sadly, the acclimation process starts all over again if the wood is transported from the yard to a new climate. In fact, if the ipe deck is moved from a humid to an arid environment, it can dry out too quickly. Rapid moisture loss can cause surface cracks and separation in any wood.

4. Ipe Wood is High Maintenance

To preserve its natural brown colors, ipe wood requires high maintenance. The only thing that needs to be done with ipe is to preserve its natural brown hue. The boards will turn silvery-gray if you don’t oil them every year.

PRO TIP

All deck sealing materials must come with a high moisture content on new wood immediately, whether it’s an oil based product or a good penetrating oil (depending on the finish desired). This is due to accelerated drying damage, which usually occurs within the first month of the deck’s construction. As a result, double coating, particularly wet on wet, is a must for long-term success.

5. Ipe Boards May Need to Be Replaced Due to Damage

Despite the fact that ipe decking wood is the most durable wood on the market, it is not impervious to damage. You will need to repair damaged boards that have broken or dried out over time.

Hot oil spills from grills can cause damage to your deck. Outdoor furniture, such as chairs and tables, will scratch your deck and even puncture it. You may need to repair a few boards if this happens.

6. Ipe Deck Boards Often Get Cupped

When a wood board is unbalanced, it has a tendency to cup. What causes this to happen? The orientation of the grain in the board will cause the board to cup on occasion (mostly happens with softwood). Most movement is caused by strong external forces.

UV rays and moisture are the two factors that do the most damage to hardwood deck boards. This is particularly true for exterior woods, which are subject to a variety of weather conditions.

Some points which accelerates cupping:

- There’s too much heat on top, and there’s too much moisture below.

- There isn’t enough space between the moisture on the ground and the deck boards’ bottoms.

- Insufficient ventilation under the deck

- Inadequate drainage under the deck

- Above the deck, there is a lot of sunshine.

- There is too much space between the deck boards

- Deck board fastening is insufficient.

7. Ipe Gets Cracks and Checks Easily

Ipe decking dries and contracts, resulting in small cracks in the face and ends of the boards. Checks are the name for these tiny cracks. Face checking is a very common occurrence that is difficult to detect. It has no effect on the durability, longevity, or water resistance of the product.

When the boards absorb moisture and extend, the checking disappears. End Checking is a form of checking that can be more troublesome. End checking occurs where moisture can escape more quickly, such as at the end of board cuts.

PRO-TIP

Use end wax to avoid end checking. When purchasing ipe wood, most suppliers would have End Wax. If one is missing, inquire about it. Anchorseal Wax Emulsion is another choice. Apply the wax to the ends of the wires before installing them.

Here is where you can get [amazon link=”B072KY1BBQ” title=”Anchorseal Wax Emulsion”/] from:

[amazon box=”B072KY1BBQ”]

8. Ipe Is Too Expensive

Brazilian Hardwoods have a luxurious feel to it. Fortunately, it isn’t in the realm of fair decking choices. Many consumers believe that using plastic or composite decking instead of ipe is more cost-efficient.

Ipe and other ironwood-rated lumber can range in price from $4 to $8 per linear foot, or up to $5.50 per square foot. The approximate cost of a 1015-foot deck, including supplies and installation, would be between $3,500 and $9,800. This is determined by labor costs in your region and the wood’s quality rating.

At the end, price is relatively subjective, a certain rate could be reasonable for some or costly for others depending on various other factors.

Cost effective alternatives for Ipe- Cumaru, Tigerwood, Garapa, Purpleheart and Massaranduba (just a beautiful and durable as Ipe).

9. Ipe is Tough to Find

Stick to Ipe wood that is branded as “premium” for the best performance, as it has the most consistent color and minimizes surface splintering. Premium Ipe, on the other hand, is often tough to obtain. One thing to keep in mind is that during Brazil’s rainy season, some retailers may run out of IPE decking.

This is due to the fact that IPE wood is only harvested for five months of the year. In South America, the wet season prohibits loggers from harvesting wood from the trees. Fortunately, IPE deck suppliers plan ahead to ensure that consumers always get what they need. It just depends on you to find the right supplier.

10. Collecting Ipe Can Be Harmful for the Environment

Despite the fact that ipe is a great wood, eco-friendly designers are avoiding it for a variety of reasons. The lack of sourcing assurance that comes with choosing ipe is perhaps the most serious problem. Ipe is an unusual species that grows in low densities. Ipe that has been approved by the Forest Stewardship Council (FSC) is available, but it isn’t widely used.

According to the Wood Database, mature trees only appear once every 3 to 10 hectares (300,000 to 1,000,000 square feet). Hectares of rainforest trees must be cleared to access such mature trees, resulting in massive deforestation and timber waste. The trees that are cut down have little or no market value and are often left unused.

Furthermore, ipe is often confused for cumaru, a South American hardwood, resulting in even more waste.

11. Ipe Can Often Get Stains or Spots

Dark stains will appear on your wood if sap, pollen, or leaves are left on the surface. Cleaning your Ipe on a regular basis will help to mitigate the impact. After you’ve swept your deck, be sure to rinse away the debris.

In areas with a lot of light, fading is common. To shield your Ipe from the sun’s harmful rays, use a UV protectant. Consider investing in a deck awning if your budget allows it.

PRO TIP

The finish of your Ipe can be protected by oiling or sealing. You can sand the spots if you prefer to let your Ipe gray naturally, but be careful not to burnish the wood. To lighten black marks or discolorations, you can use brightening chemicals available on the market. Look for a product that can be used with Brazilian hardwood without causing it harm.

12. Graying Can Occur on Ipe

Since ipe is a natural wood, if left to weather, it will eventually turn gray. The surface of an Ipe wood deck oxidizes to a silver-gray color over time, but this has no effect on the structure of the deck.

This could be prevented but requires high maintenance as said above in this post.

13. Getting Ipe Can Cause Health Issues

It all boils down to something very small but extremely dangerous, perhaps even more so than asbestos. The combination of harmful chemicals (lapachol, deoxylapachol, and lapachenole) found in the wood and the high content of Silica (Silver Dioxide or SiO2), a substance that causes a variety of health and safety issues, is what makes Ipe and other tropical hardwoods so rot-resistant.

If you’re thinking of installing Ipe, you can ask your contractor how they intend to catch and dispose of the sawdust, which is nearly impossible to do. The poisonous Silica and particles from Ipe are so small that they end up in your lungs.

After that, you and your family will be walking on it, hoping there will be no splinters or sawdust on your house.

Studies on the subject are few and far between, with the conclusion that further research is needed. But why hasn’t more research been conducted, and why has the tropical hardwood industry been holding back on testing? Take a look at how this report on a worker who acquired asthma concludes: Ipe Sawdust Research 2005.

14. Predrilling is necessary on Ipe Boards

Until inserting screws, all decking should be pre-drilled, but this isn’t like pressure-treated wood, which can compress when the screw is pushed in. Larger holes must be drilled, and only the most powerful cordless drills and drivers would be able to handle the workload of drilling through a material that is six times harder than pressure-treated pine.

It’s crucial to factor in the extra time and effort needed to build a tropical hardwood deck. Having some spare drill bits on hand is a smart idea. Don’t be surprised if a couple of them split during the installation.

15. Ipe is Brittle and Doesn’t Stick Well to Glue

If you think Ipe wood is dense and solid, you might be surprised to learn that it is also extremely brittle. This means that if you attempt to drive nails into it, the wood will crack, and if you try to send screws in, the heads will easily break.

The obvious solution to this issue is to fasten Ipe boards with stainless steel screws in pre-drilled holes. Since Ipe wood does not stick well to glue, it can be difficult to use. Woodworkers typically use all-weather yellow glue or an epoxy formula to solve this problem.

[amazon box=”B07DGZBFJM”]

Conclusion

While Ipe decking looks elegant, there are some clear problems with it. It is too hard making it difficult to drill it. Apart from that it can also be extremely brittle making it easy to break. It is too expensive and requires a lot of maintenance which can be a little problematic at times.

If you want to learn more about floors, I recommend you read our post about floating floors!

What Is a Floating Floor? Brilliant Guide to Understand Floating Floors

Floating floors can be a trendy addition to the décor of your home. There is much to know about these delightful floors that you can read about!